E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

Products

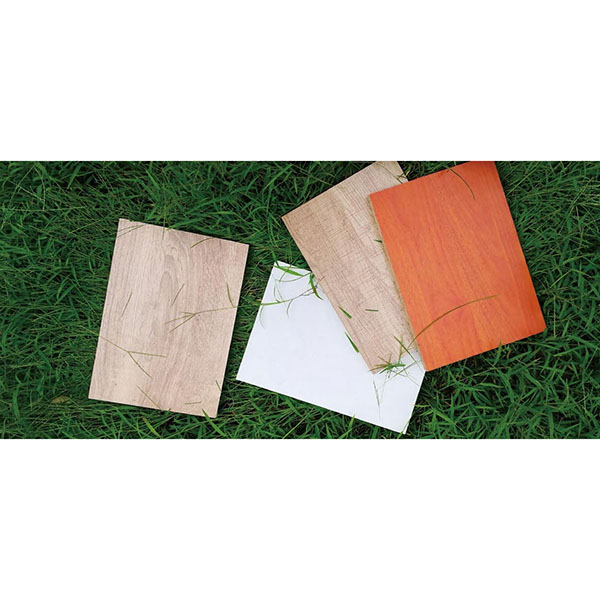

MDF

PRODUCT DETAIL

MDF is highly prized for its flawless composition and consistent density, enabling precise cutting, routing, shaping, and drilling with minimal waste and tool wear. It excels in material efficiency, machining performance, and productivity on a panel-by-panel basis. MDF offers a beautiful and uniform finish, showcasing exceptional results whether laminated, directly printed, or painted. Even when sanded with various grits, it performs admirably, accommodating thin overlays and dark paint colors. Another crucial advantage lies in its dimensional stability, virtually eliminating swelling and thickness variations. Craftsmen can trust that the precision achieved during component machining will endure in the assembled product, ensuring tight fasteners and providing end-users with an accurate fit and a clean appearance.

Common Applications

• Cabinetry

• Flooring

• Furniture

• Machining applications

• Mouldings

• Shelving

• Surface for veneers

• Wall paneling

Specifications

Dimensions

|

|

Imperial |

Metric |

|

Widths |

4 ft |

1.22 m |

|

Lengths |

up to 17 ft |

up to 5.2 m |

|

Thicknesses |

1/4-1-1/2 in |

0.6mm—40mm |

Details

|

|

Imperial |

Metric |

|

Density |

45 lbs/ft³ |

720 kg/m³ |

|

Internal Bond |

170 psi |

1.17 Mpa |

|

Modulus of Rupture/MOR |

3970 psi |

27.37 Mpa |

|

Modulus of Elasticity/MOE |

400740 psi |

2763 N/mm² |

|

Thickness Swell ( < 15mm) |

9.19% |

9.19% |

|

Thickness Swell ( > 15mm) |

9.73% |

9.73% |

|

Formaldehyde Emissions Limit |

0.085 ppm |

0.104 mg/m³ |

Standards & Certifications

|

Formaldehyde Release Rating |

Carb P2&EPA、E1、E0、ENF、F**** |

Our MDF is tested and certified to meet or exceed the following standards and certifications.

Formaldehyde Emissions Regulations-Third party certified (TPC-1) to meet the requirements of: EPA Formaldehyde Emission Regulation, TSCA Title VI.

Forest Stewardship Council® Scientific Certifications Systems Certified (FSC®-COC FSC-STD-40-004 V3-1;FSC-STD-50-001 V2-0).

We can also produce boards of different grades according to your requirements to meet different formaldehyde emission standards.