E-mail:

voyage@voyagehndr.com

E-mail:

voyage@voyagehndr.com

Products

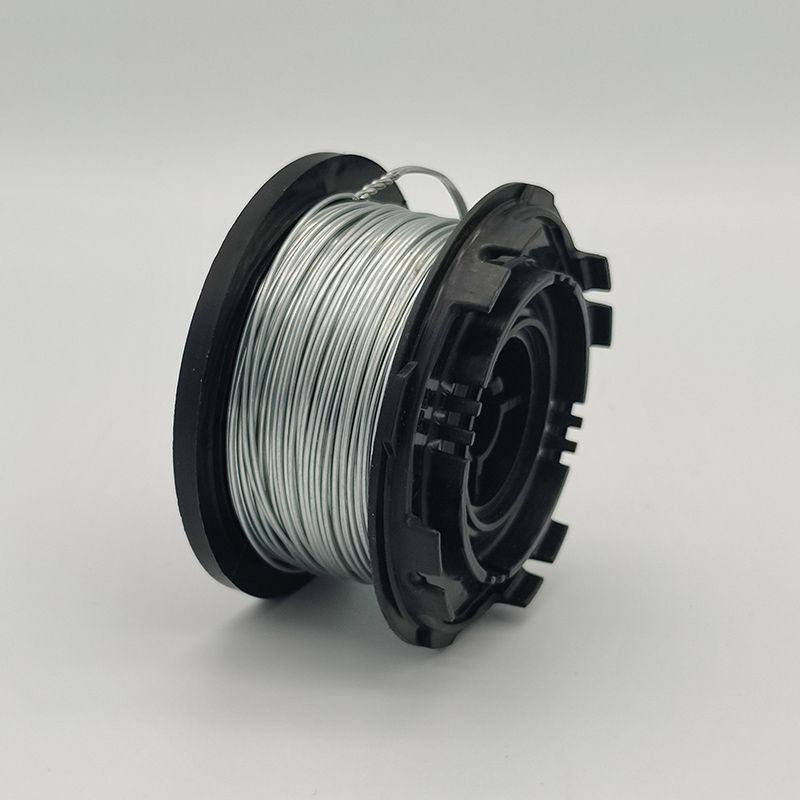

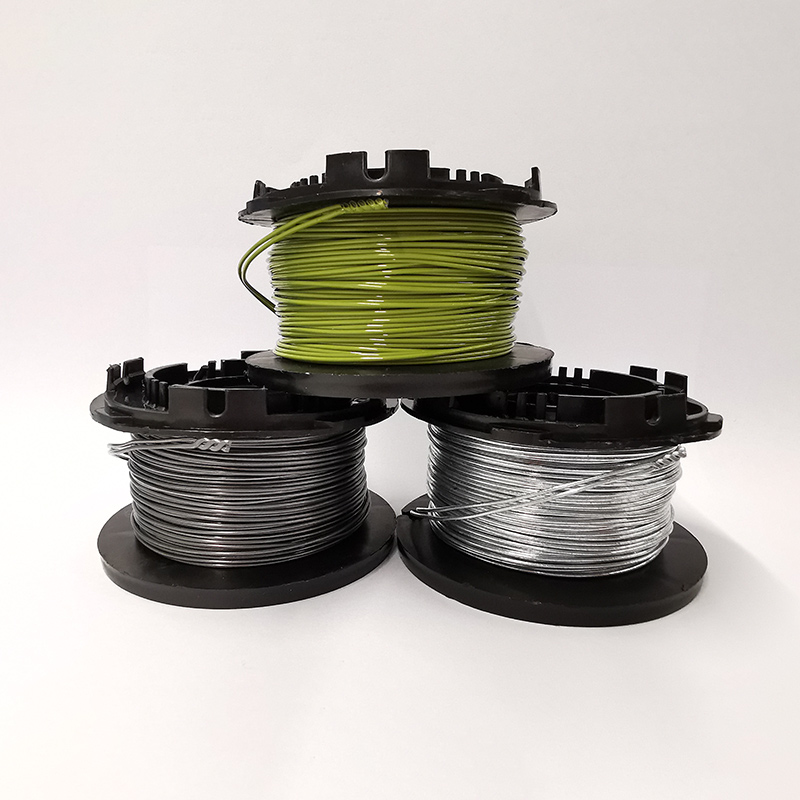

Tie wire 1061T-EG

Tie wire 1061T-EG

Our new tie wire 898 is an electro galvanized wire used exclusively for rebar tying machine. Each wire is produced with high tensile strength and flexibility that distributed evenly on it. It works perfectly on WL-400B and Max RB218, RB398, and RB518 Rebar Tiers.

Specifications

| Model | 1061T-EG |

| Diameter | 1.0mm |

| Material | Electro Galvanized wire |

| Ties per Coil | Approx.260ties(1turns) |

| Length per roll | 33m |

| Packing Info. | 50pcs/carton box, 420*175*245(mm), 20.5KGS, 0.017CBM |

| 2500pcs/pallet, 850*900*1380(mm),1000KGS, 0.94CBM | |

| Applicable models | WL460,RB-611T、RB-441T and RB401T-E and more |

Application

1) Precast concrete products,

2) building foundations,

3) road and bridge construction,

4) floors and walls,

5) retaining walls,

6) swimming pool walls,

7) radiant heating tubes,

8) electrical conduits

Note: DOES NOT WORK WITH RB213, RB215, RB392, RB395, RB515 MODELS

FAQ

What is the difference between black annealed wire and electro galvanized wire and how should I choose?

One of the most common types of wire finish is black annealed, when talking about wire is black annealed. The annealing process takes a simple post-drawn regular steel wire and heats it using an oven or kiln changing the chemical composition. This process softens the wire and changing its color from almost a rough grey or silver to more black or brown color.Black annealed bale ties gives a black or dark look and feel slightly oily. Using a black annealed wire, you may want to notice that the wire has between 5-10% more elongation making it more ideal for tying materials that expand a bit afterwards.

Electro galvanized wire on the other hand, goes through the process of coating or bathing raw steel or “bright basic” wire in a pool of molten zinc. The process of galvanization allows the wire to be used in wet and humid environment without compromising its structural integrity. Galvanized wire is one of the most durable and versatile types of finishes, particularly when storing your wire in an outdoor area.